The automobile sector has regularly been on the cutting edge of technological excellence. However, the velocity and breadth of reorganization in the last several years have been truly breathtaking.

Every factor of car manufacturing is being altered by technology, from digital design and 3D printing to artificial intelligence and robotics.

This article will analyze the numerous ways technology is turning the sector on its head – the commercial and safety implications, and the potential of what our automobiles will accomplish.

As manufacturers strive for more malleable and efficient methods for producing, these other issues are becoming more vital. Specifically, with the aid of a Better Bid's VIN decoding, such processes grow more comfortable to care for than ever before. In this environment, information is essential, and the opportunity for higher-than-ever quality and compliance from the start can be assured by manufacturers.

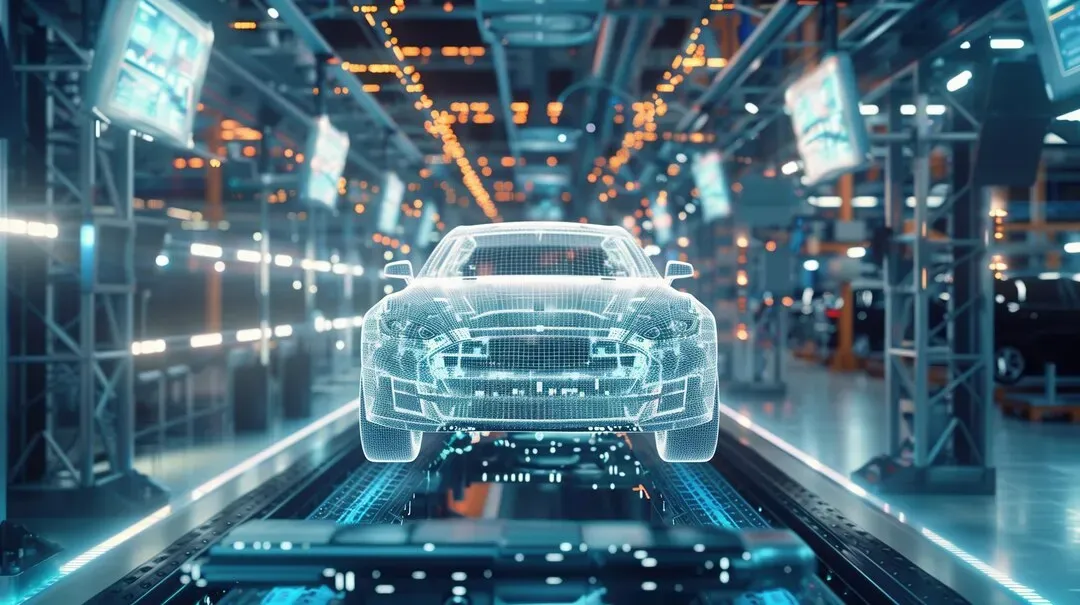

Digital Design and Simulation

The design episode has been fully upended by the impact of CAD software. Engineers may build a mature 3D design of a vehicle or car before a physical model is constructed. Not only that but these designs can be analyzed before a single dollar is spent on tooling. Thus, a car’s appearance and behaviour can be tested electronically under a variety of conditions.

Although robotics have been common in car manufacturing since the 1960s, many developed countries’ contemporary production lines have recently started employing them to an increasing extent after significant developments in the field of AI and robot dexterity.

Robots can do complex tasks that require precisely working with small objects and devices, and in assembly lines with humans, they assemble engines, monomers, and the intricate dashboard detective mechanism.

In addition, this new type of production has enabled car producers, for example, to utilize IoT sensors in the robots and thus receive a continuous data stream that allows predictive maintenance.

3D Printing Advancements

3D printing, also called additive manufacturing since it is used to build the monomers rather than the sum of the parts by subtracting, is expected to revolutionize the entirety of car production.

The primary reason for the enthusiasm surrounding it is that companies can develop monomers as they go – and with complex shapes, which cannot be developed in any other way invoicing the manufacturer to pay a stiff bill for the waste when manufacturing traditional monomers in the trial stage.

Electrification and Battery Technology

Electrification and new EV batteries are probably the most newsworthy. New battery technology advancements make it much easier and cheaper to use EVs. Modern lithium-ion batteries store far more energy and have a far longer lifespan than the old lead-acid batteries.

New solid-state batteries that are now being commercialized promise even swifter charging and more extended capacity. Car manufacturers are now investing a tremendous sum of money into this particular field.

AI and Machine Learning

AI has two primary effects on car manufacturing. First, artificial intelligence algorithms are used in production, where they optimize supply chains and inventories so that all necessary parts are just in time without overstocking.

Second, on-vehicle AI is used for advanced driver-assistance systems, such as autonomous braking, lane-keeping assist, and more fully autonomous driving technologies. The latter not only improves the vehicle's safety but opens up new possibilities for its use.

Quality Control and Testing

Besides, technology changed the requirements for control and testing in car manufacturing. Currently, high-resolution cameras and sensors are used in car production to monitor all stages and quickly reveal defects.

Further, such data is analyzed by machine learning algorithms, which can recognize some patterns in mistakes and find their source. With such control, every car can be quality assured before arriving at the factory floor minimalizing recalls and increasing customer trust.

Environmental Impact

One of the big no-good effects of car manufacturing is high levels of emissions and waste during production. Still, modern recycling rates and the new legal framework on emissions are forcing manufacturers to reconsider their technologies.

In particular, the modern technologies of car manufacturing reduce waste and use recycled materials. The production of electric cars, which tech is also evolving, is seen as an opportunity to save the transported into the atmosphere.

To sum up, the modern technology of car manufacturing makes cars safer, more efficient, and environmentally friendly. With continuous improvement, such evolution leads the auto industry. In the future, the process of car manufacturing is not only about speeding up but also making the driver’s life more secure and more suited to modern life.